V-Belts Dealers - Nahata Industrial Stores

- Shridhar GK

- Apr 8

- 3 min read

Contact : +91 9448278508

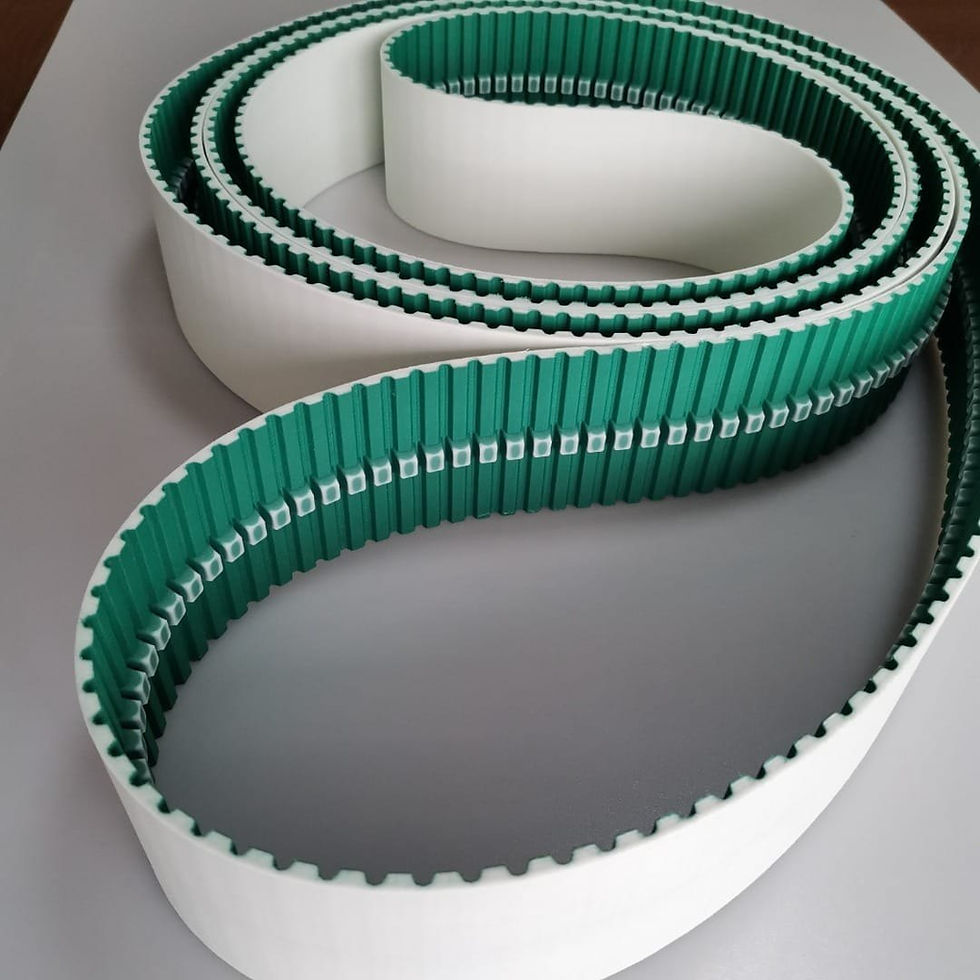

In today's industrial landscape, V-Belts play a vital role, yet they often remain overlooked. These belts are essential for transmitting power between pulleys, ensuring that machines run smoothly. At Nahata Industrial Stores, a leading supplier of V-Belts, recognizing the importance of this component is crucial for maintaining efficient operations.

What are V-Belts?

V-Belts are mechanical belts that transfer power from one rotating shaft to another. They have a trapezoidal shape, which allows them to fit tightly into pulley grooves. This design maximizes grip, minimizes slippage, and makes them critical for various machinery, from lawnmowers to conveyor systems.

V-Belts come in many sizes and materials, allowing them to meet specific application needs. For instance, a high-quality V-Belt can improve the efficiency of machines by up to 30%, leading to substantial energy savings. Proper selection can significantly impact both performance and operating costs.

Importance of Quality V-Belts

The main purpose of a V-Belt is to effectively transfer energy. High-quality V-Belts are designed to handle high tensions, resist wear, and perform efficiently under different conditions. Research indicates that using subpar belts can lead to breakdowns, resulting in repair costs that can reach 20-30% of total equipment costs annually.

Opting for quality may seem costly initially, but the long-term benefits are clear. Nahata Industrial Stores offers top-of-the-line V-Belts to help you avoid costly interruptions and maintain machinery stability. A quality belt can last longer and keep your machinery running without unexpected downtime.

Types of V-Belts

Different types of V-Belts serve various functions. Knowing these can help you choose the right belt. Here are the most common types:

Classical V-Belts: These are standard options for general use, providing reliable power transmission for everyday applications.

Wedge V-Belts: Designed with a narrower profile, these belts are built for heavy-duty applications, offering increased load-bearing capacity and power transmission.

Narrow V-Belts: Similar to classical belts but designed for tighter spaces, they maintain the same power capabilities.

Variable Speed Belts: Perfect for applications requiring frequent speed changes, such as in conveyor systems.

Choosing the right belt based on the machine's specific demands can maximize efficiency and reduce energy costs.

Why Choose Nahata Industrial Stores?

Nahata Industrial Stores has established a strong reputation in V-Belt distribution, standing out for several reasons:

Wide Selection: The store offers a comprehensive range of V-Belts, ensuring that customers can find belts suited to their specific machinery needs.

Expert Guidance: In addition to quality products, Nahata provides personalized consultations. Their knowledgeable staff helps clients select the perfect V-Belt for their applications.

Competitive Pricing: Though quality is crucial, Nahata is committed to maintaining competitive prices, allowing access to premium products for every budget.

Customer Support: Exceptional customer service is key at Nahata. They provide ongoing support to help clients at every stage, from selection to installation and beyond.

Maintenance Tips for V-Belts

Choosing quality V-Belts is just the first step. Regular maintenance is essential to extend their lifespan and improve performance:

Regular Inspections: Frequently check for signs of wear, such as cracks or fraying. Early detection can prevent failures that may lead to downtime.

Proper Tensioning: Belts that are too loose may slip, causing damage, while those that are too tight can increase wear. Aim for the manufacturer-recommended tension.

Alignment Checks: Ensure that pulleys are properly aligned. Misalignment can cause uneven wear, reducing the lifespan of your V-Belts.

Cleaning: Keeping belts and pulleys clean helps maintain performance. Dirt and debris can lead to slippage, reducing efficiency.

Replacement Schedule: Develop a plan for replacing V-Belts based on usage frequency and manufacturer recommendations. Regular replacements can save costs in the long run.

Implementing these maintenance practices will significantly enhance the longevity and effectiveness of your V-Belts, ensuring smooth machinery operation.

The Future of V-Belts

As technology progresses, V-Belts are becoming more advanced. The focus on energy efficiency and sustainability is pushing manufacturers to innovate with new materials and designs. For example, some newer belts can reduce energy losses by up to 25%.

Nahata Industrial Stores stays current with these trends, always refreshing their inventory to provide clients with the most innovative options available. This commitment ensures that customers benefit from cutting-edge V-Belt technology.

Final Thoughts

While V-Belts might not be the most attention-grabbing components in machinery, their significance is undeniable. Understanding their function, types, and impact on efficiency is essential for anyone working in industrial settings. Nahata Industrial Stores is ready to provide high-quality V-Belts along with expert advice, helping you optimize your machinery's performance.

Investing in superior V-Belts and adhering to maintenance guidelines can drastically improve operational efficiency and lower costs. When evaluating your industrial needs, remember the essential role of V-Belts and the resources available at Nahata Industrial Stores.

Comments